How A Microchip Is Made?

Microchips, the tiny but powerful components at the heart of modern technology, are ubiquitous in our daily lives, from smartphones to computers to cars. Have you ever wondered how these intricate pieces of technology are made? Understanding the process of microchip manufacturing can provide insight into the complexity and precision involved in creating these essential devices. This article delves into the fascinating world of microchip production, exploring the design process, semiconductor material selection, manufacturing techniques, testing procedures, and final assembly that culminate in the creation of these miniature marvels.

1. Introduction to Microchips

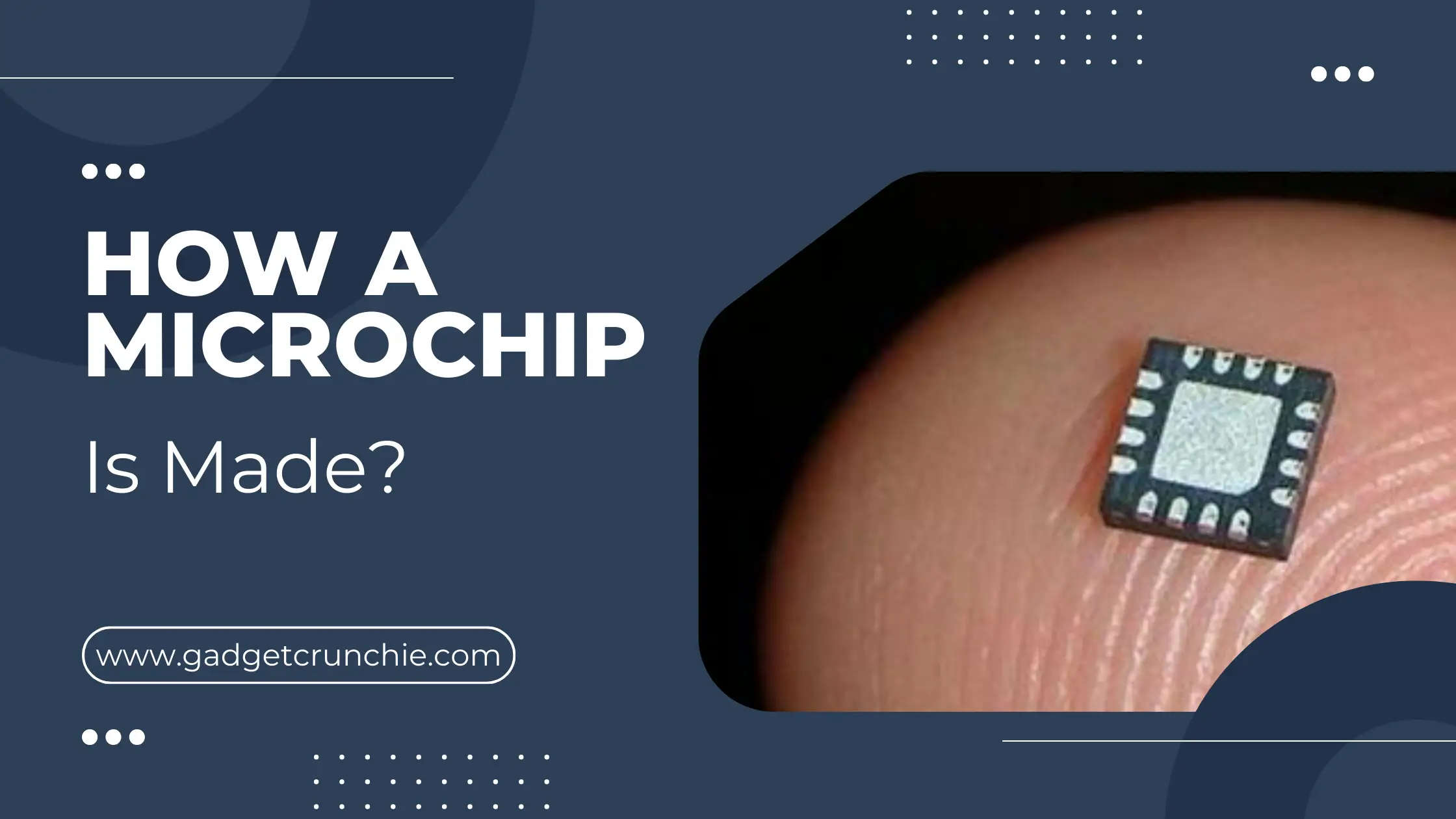

What is a Microchip?

Ah, the humble microchip – the tiny brain behind all our beloved gadgets. A microchip, also known as an integrated circuit, packs a ton of electronic components onto a small piece of semiconductor material. Think of it as the Swiss Army knife of the tech world.

Importance of Microchips in Modern Technology

Let’s face it, without microchips, our world would be as functional as a toaster in a bathtub. These tiny wonders power everything from smartphones and laptops to cars and even spacecraft. Basically, microchips are the unsung heroes that keep our tech-savvy lives running smoothly.

2. The Design Process

Creating a Blueprint

Before diving into the manufacturing process, designers whip up a detailed blueprint of the microchip’s layout. It’s like planning out a miniature city, but with electrons zipping around instead of tiny cars.

Software Simulation and Modeling

To avoid any “oopsies” down the line, engineers use fancy software to simulate how the microchip will behave under different conditions. It’s like playing a high-stakes game of Sims, but instead of virtual families, it’s all about optimizing performance.

3. Semiconductor Material Selection

Silicon as the Primary Material

When it comes to semiconductor materials, silicon is the Beyoncé of the bunch. It’s abundant, stable, and plays well with others – making it the go-to choice for crafting microchips. Plus, who can resist that shiny, atomic structure?

Doping for Functionality

No, we’re not talking about Lance Armstrong here. Doping in the semiconductor world involves adding specific impurities to silicon to tweak its electrical properties. It’s like giving your morning coffee an extra shot of espresso for that added kick.

4. Photolithography and Etching

Pattern Transfer with Photomasks

Photomasks come into play to carve out the intricate circuit patterns on the silicon surface. They act as stencils, guiding light to transfer the design onto the semiconductor material. It’s like creating a high-tech tattoo for the microchip.

Chemical Etching for Precision

Once the pattern is transferred, chemical etching steps in to etch away the unwanted parts of the silicon substrate. It’s like sculpting a tiny masterpiece with precision and finesse, ensuring every circuit is in its right place.

And there you have it – a crash course on how the unsung heroes of technology, microchips, come to life!

5. Deposition and Integration

Layering Techniques for Circuitry

Once the design is laid out, it’s time to get those microscopic gears turning. Layering techniques are employed to deposit various materials onto the silicon wafer, building up the intricate circuitry that will make your microchip tick. Think of it as a hi-tech assembly line for the tiniest of workers.

Metalization for Interconnections

Just like building a network of highways to connect cities, metalization is key to forging pathways between different components on the chip. These metal layers serve as the conduits that allow electrons to zip around, ensuring your microchip functions like a well-oiled machine.

6. Testing and Quality Control

Functional Testing and Debugging

Before a microchip leaves the nest, it undergoes rigorous testing to make sure it’s firing on all cylinders. Engineers put these tiny powerhouses through their paces, checking for any hiccups and ironing out any kinks in the system. It’s like giving your new car a test drive, except on a molecular level.

Quality Assurance Processes

Quality is the name of the game in the world of microchips. Stringent quality assurance processes are put in place to ensure that each chip meets the highest standards of performance and reliability. After all, you wouldn’t want your smartphone crashing mid-text, would you?

7. Packaging and Final Assembly

Encapsulation for Protection

Just like putting a delicate flower in a sturdy vase, microchips are encapsulated in protective packages to shield them from the harsh realities of the outside world. This packaging not only safeguards the chip from physical damage but also shields it from environmental hazards like moisture and dust.

Final Testing and Verification

Before bidding adieu to the microchip, one last round of testing is conducted to make sure everything is humming along as it should. This final verification ensures that the chip is up to snuff and ready to tackle whatever tasks you throw its way. It’s the grand finale before the microchip sets off on its journey to power your devices.

Conclusion

The journey of a microchip from raw materials to the intricate circuits that power our devices is a testament to human ingenuity and technological advancement. By gaining a deeper understanding of how microchips are made, we can better appreciate the innovation and expertise that go into the devices we rely on every day. So next time you hold a smartphone or use a computer, take a moment to marvel at the remarkable process that brings these microchips to life, shaping the world of technology as we know it.